fob price $ 3,480.00

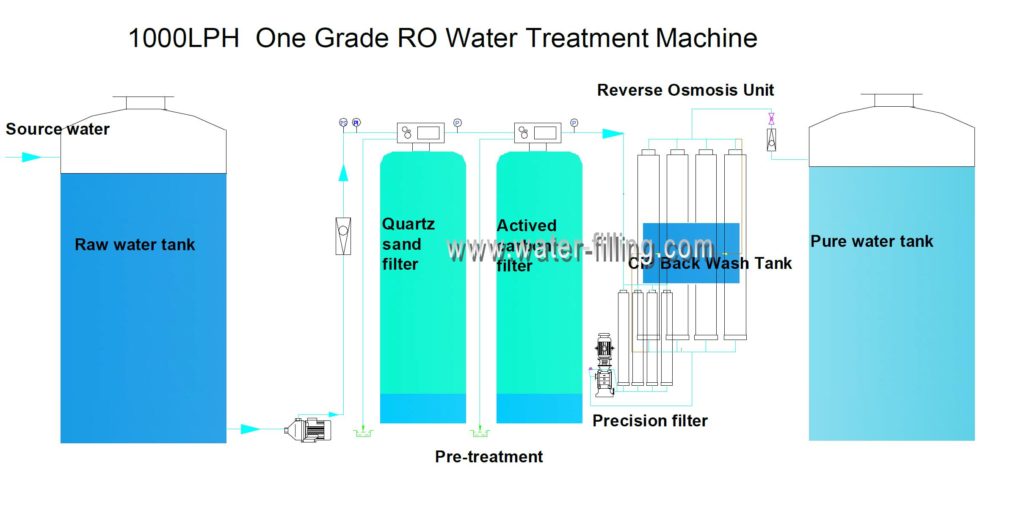

1000 LPH RO Water Purification Machine for producing purified water. Its producing capacity is 1000 liter per hour. It is the bestselling purified water purification machine for pure water plant and mineral water plant.

RO water purification machine will removed all contaminants, like solids, bacteria, algae, viruses, fungi, minerals such as iron, manganese and sulphur, and man-made chemical pollutants including fertilisers.

| Capacity purified water | 1000 Liter per hour |

| Cost raw water | 1300 Liter per hour |

| RO membrane | 4 psc 4040 |

| Quartz sand filter | Flow: 2 ton per hour Media: 100 kg carbon |

| Active carbon filter | Flow : 2 ton per hour Media: 50 kg of quartz sand |

| Precision filter | Three set PP filter PP30-40 Flow 2M3 |

Technique Parameter of 1 Ton RO Water Purification

1000LPH Reverse Osmosis Water Purification system

Output water quality: Accord with National bottle drinking water standard GB17323-2008.

Capacity of producing water: 1000L/H (25℃)

Rate of desalination: ≥97%

Wooden packing

Main contracture of the filtering system:

Quartz sand filter, active carbon filter, Precision filter, Reverse Osmosis system, Membrane cleaning system, control system, Ozone generator

System requirements for outside plant

Inlet pipe: The inlet pipe are buried one meter away from the water treatment area

Outlet pipe: The outlet pipes are long enough to the product water pump valve (This to be decided after the plan sketch is provided)

Water drain: Drained out in ditch of plant (decided and built by the user)

Functions of RO Water Purification :

RO membranes auto wash and manual wash

RO membranes manual wash with medicine

Pure water high water level auto stop, low water level auto start

Multi-phases pump protected without water

Protected when no power, poor power, over electrical current, short circuit, circuit breaker, leakage protection.

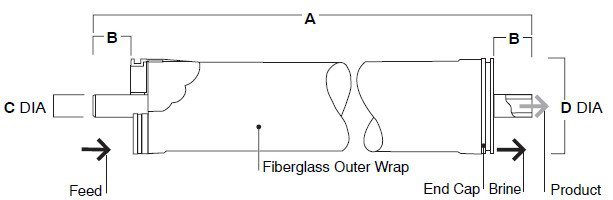

The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The treated water and the untreated water are separated by the membrane; the treated water osmoses to the untreated water. There is osmotic pressure between the two. If the pressure is added to the untreated water and the pressure of the untreated water is bigger than the osmotic pressure, the water of the untreated water osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the untreated water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water.

The water must be pretreated before entering into the RO system, or it will bring damage to the RO membrane.

The RO system not only can be used for desalination, but also for filtering the organic substance and bacteria.

The production of water is monitored by the liquid crystal display conductivity meter.

The RO system needs be cleaned timely, including the stainless steel pump, filter, disinfectant tank, valve and other components.

Commonly, the RO system should work once every day. If it does not work in one week, it must be protected by some measures, or the service life of the membrane will be serious affected.

RO device employs low pressure large flux membrane made by American Dow Company. The type is American Dow BW30-4040 Ro Memebrane, and it has nine of them. The membranes can serve for years in good maintenance. This instruction explains the details of operation and maintenance methods. The RO device removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The water and the solution are separated by the membrane; the water osmoses to the solution. There is osmotic pressure between the two. If the pressure is added to the solution and the pressure of it is bigger than the osmotic pressure, the water of the solution osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the raw water is purified into the pure water through the RO membrane under adequate pressure. The left water which can not osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water. This principle makes RO device.

CIP Back Washing System

In RO operating process, as the in-water contains traces of suspended solids and colloidal, salt, metal oxides and impurities such as bacteria. After a period of time, membrane fouling and easily makes the membrane layer of sediment flux coverage to decline rapidly. So regular cleaning and disinfection is the necessary link to maintain the normal operation of the RO water purification system.

Back Smart structure

What Is purified Water ?

RO water purification will remove all item of raw water to produce purified water. The purified water do not included any mineral. All item should write zero. Human being drinking other water which have suspendid or item. When they drinking purified water, they will feeling a little sweet because its complete pure.

What is the Reverse osmosis Water Purification?

Reverse osmosis water purification is made use of pressure as impetus to difference the purified water from the raw liquid. It give pressure to raw liquid. When the pressure exceeds its osmotic pressure. The pure water will reverse osmosis against the direction of natural osmosis. So that got the purified water at the low pressure side of the membrane. And another side is the waste water.